FREE CHECKLIST FOR CORRUGATED BUYERS:

Presented by Lex Cisler of IPS Packaging

ATTENTION Corrugated Buyers:

Learn the Top 4 Mistakes That Are Costing Most Companies $50K+ per Year...

(and How to Avoid Them)!

In 10 minutes learn how to avoid the 4 key mistake in order to optimize your packaging, cut costs, and improve warehouse efficiency.

Claim Your Copy & Start Saving

This FREE Checklist is for you if:

You’re tired of overpaying for packaging materials and want to uncover hidden cost-saving opportunities.

Your current packaging designs are inefficient—either over-engineered and expensive or under-engineered and leading to product damage.

Vendor delays and lack of flexibility are causing bottlenecks in your operations.

You’re managing multiple packaging vendors and need a streamlined, consolidated solution.

Your company is struggling to maintain competitive pricing and you’re unsure how to hold vendors accountable.

You want to reduce inventory storage costs by leveraging Just-in-Time delivery capabilities.

What’s Covered in the Checklist:

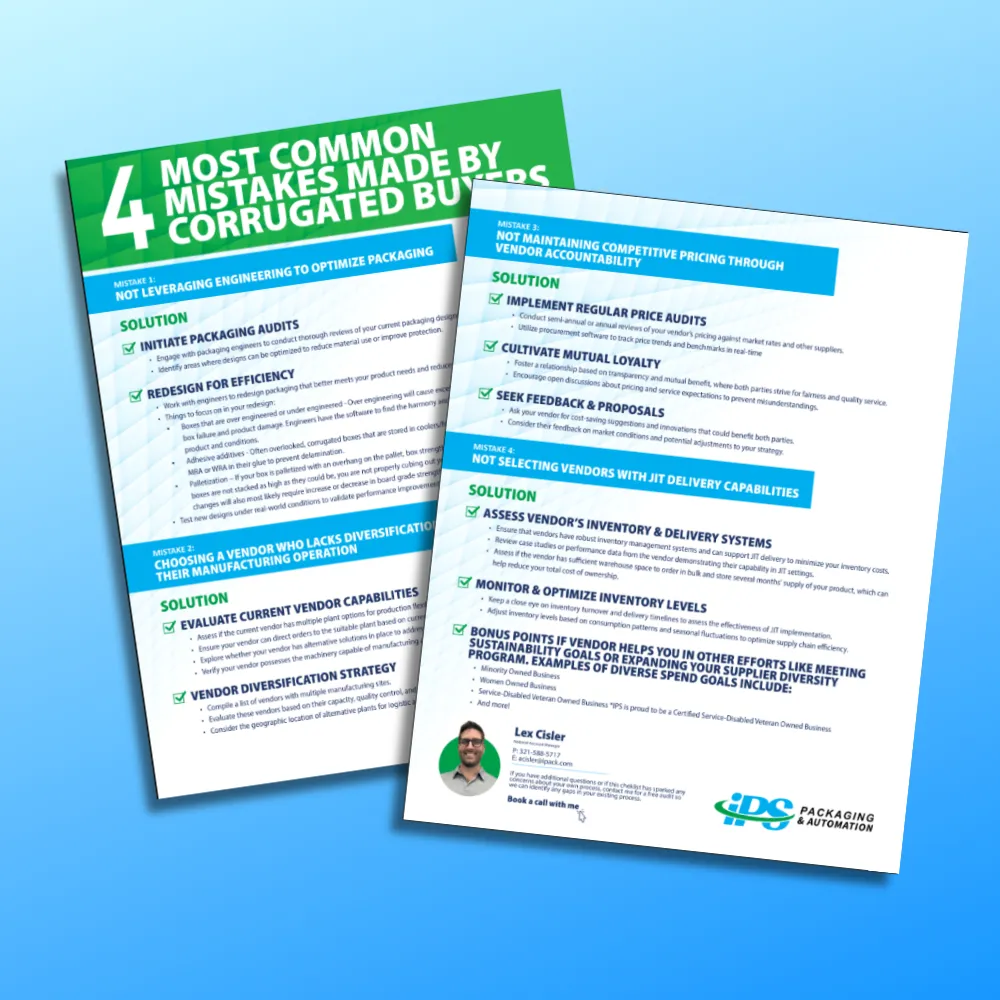

1. Not Leveraging Engineering to Optimize Packaging

Learn how to redesign packaging for cost savings and performance.

2. Choosing a Vendor Without Manufacturing Flexibility

Discover strategies for ensuring your vendor meets your needs.

3. Failing to Maintain Competitive Pricing Through Vendor Accountability

Execute price audits and foster vendor transparency.

Ignoring Vendors Without Just-in-Time Delivery Capabilities

Reduce inventory costs and streamline your supply chain.

MEET your Packaging & Automation Expert

Hey, I'm Lex!

I have spent the last 15+ years working with some of the best companies in the world develop and deploy their packaging and automation solutions.

With all that experience, I wanted to package (pun intended) all of what I have learned into resources for companies that want to:

Learn how to cut costs

Improve sustainability

Reduce damaged goods

Learn how to incorporate automation

Let me know what you think of the Checklist, and if you want more help and would like a Free Packaging Audit to find ways to improve your business, just use the link below!